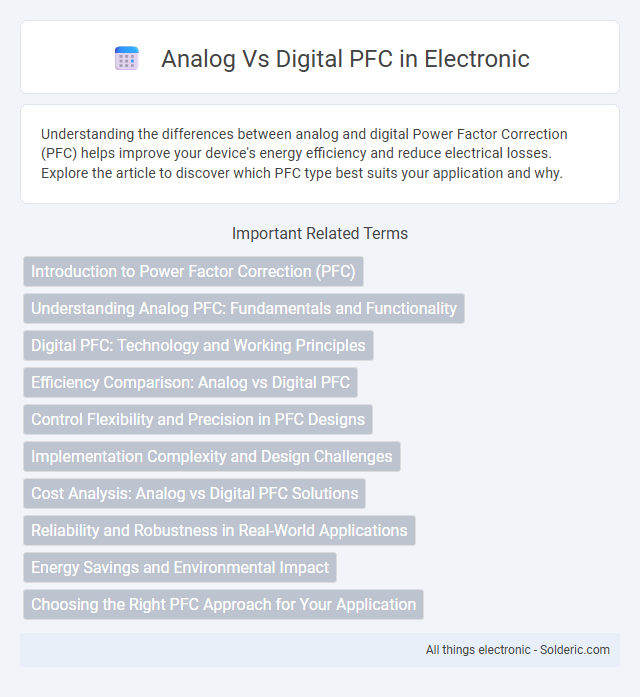

Understanding the differences between analog and digital Power Factor Correction (PFC) helps improve your device's energy efficiency and reduce electrical losses. Explore the article to discover which PFC type best suits your application and why.

Comparison Table

| Feature | Analog PFC | Digital PFC |

|---|---|---|

| Control Method | Continuous analog control | Microcontroller or DSP-based control |

| Precision | Lower accuracy, susceptible to component variations | High accuracy with programmable parameters |

| Flexibility | Fixed design, limited adaptability | Easily reconfigurable via firmware updates |

| Complexity | Simple circuitry | Complex hardware and software integration |

| Cost | Lower initial cost | Higher initial cost due to processor and software |

| Efficiency | Moderate efficiency | Higher efficiency with advanced algorithms |

| Response Time | Faster response to rapid changes | Slower due to processing delay |

| Diagnostics & Monitoring | Limited or no built-in diagnostics | Comprehensive monitoring and fault detection |

| Application | Low to medium power applications | High power, complex systems |

Introduction to Power Factor Correction (PFC)

Power Factor Correction (PFC) improves the efficiency of electrical power systems by minimizing reactive power and aligning voltage and current waveforms. Analog PFC employs continuous control circuits such as operational amplifiers and comparators to regulate power quality, while digital PFC uses microcontrollers or DSPs for programmable, adaptive correction. Digital PFC offers advantages in precision and flexibility, whereas analog PFC provides simplicity and cost-effectiveness in basic applications.

Understanding Analog PFC: Fundamentals and Functionality

Analog Power Factor Correction (PFC) utilizes continuous control signals to adjust the input current waveform, reducing harmonic distortion and improving power efficiency in electrical systems. It operates through analog components like operational amplifiers and comparators, enabling real-time response to changes in load and voltage conditions for stable operation. This method ensures consistent correction performance by dynamically regulating the phase angle between voltage and current, crucial for minimizing reactive power and compliance with energy standards.

Digital PFC: Technology and Working Principles

Digital Power Factor Correction (PFC) utilizes microcontrollers or digital signal processors (DSPs) to precisely control the input current waveform, aligning it with the input voltage to improve power factor and reduce harmonic distortion. This technology employs real-time sampling and adaptive algorithms to dynamically adjust switching frequency and duty cycles, enhancing efficiency and response to varying loads. The ability to implement advanced control strategies and diagnostics in software makes digital PFC highly flexible and scalable compared to analog counterparts.

Efficiency Comparison: Analog vs Digital PFC

Digital Power Factor Correction (PFC) offers higher efficiency than analog PFC due to precise control algorithms and adaptive response to varying load conditions. Analog PFC circuits typically exhibit efficiency ranging from 90% to 95%, while digital PFC systems can achieve efficiencies exceeding 98% by minimizing switching losses and optimizing power delivery. Enhanced real-time monitoring and adjustment capabilities in digital PFC contribute to better power quality and overall system performance.

Control Flexibility and Precision in PFC Designs

Digital PFC offers superior control flexibility and precision by enabling programmable algorithms that adapt to varying load conditions and system requirements. Analog PFC relies on fixed component values, limiting adaptability and fine-tuning capabilities for optimal power factor correction. Your choice impacts efficiency and performance, with digital solutions providing enhanced accuracy in maintaining power quality under dynamic operational scenarios.

Implementation Complexity and Design Challenges

Analog PFC circuits typically feature simpler implementation with fewer components, making them cost-effective but less flexible in handling varying load conditions and transient responses. Digital PFC offers advanced control capabilities through microcontrollers or DSPs, enabling precise tuning and adaptive algorithms, yet it demands complex firmware development and careful management of switching noise and processing delays. The design challenges of digital PFC center on real-time processing requirements and ensuring system stability under diverse operating conditions.

Cost Analysis: Analog vs Digital PFC Solutions

Analog PFC solutions generally offer lower upfront costs due to simpler circuitry and fewer components, making them suitable for budget-sensitive applications. Digital PFC systems involve higher initial investment because of microcontrollers and programming requirements but can realize cost savings over time through improved energy efficiency and reduced maintenance. Your decision should weigh the balance between immediate expenditure and long-term operational savings when selecting between analog and digital PFC technologies.

Reliability and Robustness in Real-World Applications

Analog PFC circuits offer proven reliability in straightforward applications due to their simplicity and fewer components, reducing failure points in harsh environments. Digital PFC systems provide enhanced robustness by enabling adaptive control algorithms and real-time monitoring, which optimize performance and fault tolerance under varying load conditions. Both analog and digital PFC designs can achieve high reliability, but digital PFC excels in complex, dynamic applications requiring precise power factor correction and system diagnostics.

Energy Savings and Environmental Impact

Analog Power Factor Correction (PFC) circuits typically offer less precise control, leading to lower energy efficiency and higher harmonic distortion, which increases environmental impact through wasted electricity and greater emissions. Digital PFC systems enable finer control and adaptability, resulting in optimized energy savings by reducing reactive power and minimizing losses in electrical systems. Enhanced efficiency from digital PFC directly supports reduced carbon footprints and contributes to sustainable energy consumption practices.

Choosing the Right PFC Approach for Your Application

Selecting the right Power Factor Correction (PFC) approach depends on your application's complexity and cost sensitivity. Analog PFC offers simplicity and cost-effectiveness for basic power supply designs, while Digital PFC provides enhanced precision, adaptability, and advanced control for complex systems requiring optimized energy efficiency. Consider your performance requirements, budget constraints, and system flexibility when deciding between analog and digital PFC solutions.

Analog vs Digital PFC Infographic

solderic.com

solderic.com