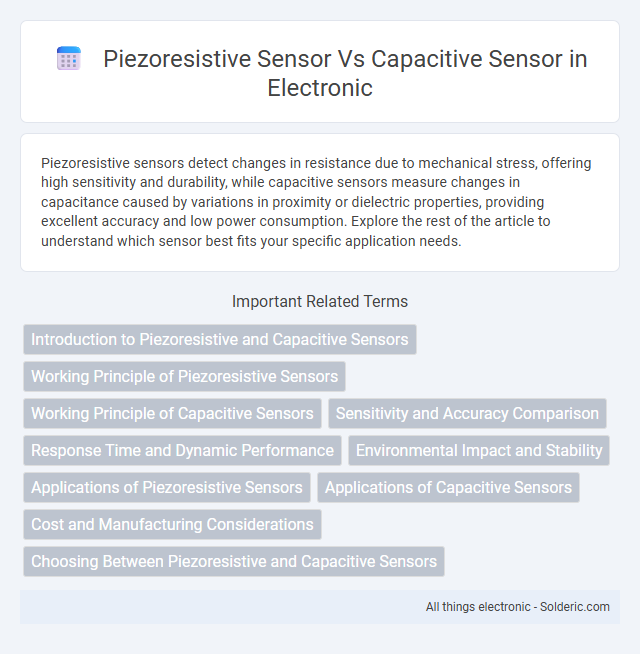

Piezoresistive sensors detect changes in resistance due to mechanical stress, offering high sensitivity and durability, while capacitive sensors measure changes in capacitance caused by variations in proximity or dielectric properties, providing excellent accuracy and low power consumption. Explore the rest of the article to understand which sensor best fits your specific application needs.

Comparison Table

| Feature | Piezoresistive Sensor | Capacitive Sensor |

|---|---|---|

| Sensing Principle | Change in electrical resistance due to applied mechanical stress | Change in capacitance caused by displacement or dielectric changes |

| Sensitivity | High sensitivity to strain and pressure | Moderate to high sensitivity, depends on design |

| Linearity | Generally linear response | Highly linear over operating range |

| Temperature Stability | Affected by temperature variations, may need compensation | Better temperature stability, less drift |

| Power Consumption | Requires constant current or voltage | Typically low power consumption |

| Durability | Robust but sensitive to physical damage | Highly durable, less prone to mechanical wear |

| Applications | Pressure sensors, accelerometers, strain gauges | Touch screens, proximity sensing, humidity sensors |

| Output Type | Analog resistance change, converted to voltage/current | Analog or digital capacitance value |

| Cost | Generally low cost, simple fabrication | Moderate cost, more complex fabrication |

Introduction to Piezoresistive and Capacitive Sensors

Piezoresistive sensors detect mechanical strain by measuring changes in electrical resistance, making them highly sensitive to pressure, force, and acceleration. Capacitive sensors operate by detecting variations in capacitance caused by changes in the distance or dielectric properties between conductive plates, commonly used for touch input and proximity sensing. Both sensor types are essential in various applications, offering distinct advantages in sensitivity, accuracy, and environmental adaptability.

Working Principle of Piezoresistive Sensors

Piezoresistive sensors operate based on the change in electrical resistance of a material when mechanical stress is applied, causing deformation in the sensor's structure. This deformation alters the resistance of the piezoresistive elements, which is then measured to determine the magnitude of the force, pressure, or strain. Unlike capacitive sensors that detect changes in capacitance due to displacement or dielectric variations, piezoresistive sensors provide direct electrical resistance output proportional to mechanical stress.

Working Principle of Capacitive Sensors

Capacitive sensors operate by detecting changes in the electrical capacitance caused by the proximity or displacement of an object. The sensor consists of two conductive plates separated by a dielectric material, and the capacitance varies when the object's presence alters the electric field between the plates. This principle enables capacitive sensors to achieve high sensitivity and accuracy in measuring position, pressure, and humidity.

Sensitivity and Accuracy Comparison

Piezoresistive sensors exhibit higher sensitivity due to their resistance change under mechanical stress, making them ideal for detecting small pressure variations with precise output. Capacitive sensors offer superior accuracy in stable environments by measuring changes in capacitance with minimal signal drift and low noise interference. The choice between piezoresistive and capacitive sensors depends on the specific application requirements for sensitivity and measurement precision.

Response Time and Dynamic Performance

Piezoresistive sensors exhibit rapid response times typically in the microsecond range, making them well-suited for high-speed dynamic applications such as vibration and impact monitoring. Capacitive sensors generally have slower response times, often in the millisecond range, due to their reliance on changes in electric field and capacitance, which can introduce filtering effects. The dynamic performance of piezoresistive sensors outperforms capacitive types in applications requiring fast transient detection and real-time feedback.

Environmental Impact and Stability

Piezoresistive sensors exhibit higher sensitivity but are more vulnerable to environmental factors like temperature fluctuations and mechanical stress, which can affect their long-term stability. Capacitive sensors offer superior environmental stability due to their non-contact measurement principle, making them less prone to drift and temperature-induced errors. Choosing the right sensor for your application involves balancing environmental impact with the desired stability and reliability.

Applications of Piezoresistive Sensors

Piezoresistive sensors are extensively used in automotive systems for pressure measurement, such as tire pressure monitoring and engine control. They are also crucial in biomedical devices like blood pressure monitors and wearable health trackers due to their high sensitivity and reliability. Industrial applications include force sensing in robotics and structural health monitoring where precise stress and strain detection is essential.

Applications of Capacitive Sensors

Capacitive sensors excel in applications requiring precise proximity and position detection, such as touchscreen devices, fluid level monitoring, and humidity measurement. Their ability to detect changes in dielectric properties makes them ideal for non-contact sensing in industrial automation and consumer electronics. You can rely on capacitive sensors for durable, high-resolution detection in environments where touch sensitivity and minimal wear are critical.

Cost and Manufacturing Considerations

Piezoresistive sensors typically offer lower production costs due to simpler fabrication processes using semiconductor materials and fewer assembly steps, making them suitable for mass production. Capacitive sensors often involve more complex manufacturing techniques, including precise electrode alignment and insulating layer deposition, which can increase overall costs. The choice between these sensors depends on budget constraints and the required production volume, with piezoresistive sensors favored for cost-sensitive applications.

Choosing Between Piezoresistive and Capacitive Sensors

Choosing between piezoresistive and capacitive sensors depends on application-specific requirements such as sensitivity, environmental conditions, and measurement range. Piezoresistive sensors excel in high-sensitivity applications with dynamic force detection and operate well under varying temperatures, while capacitive sensors offer superior resolution for detecting minute changes in displacement or pressure with minimal noise interference. Considering factors like power consumption, durability, and response time ensures optimal sensor performance tailored to industrial automation, healthcare devices, or consumer electronics.

piezoresistive sensor vs capacitive sensor Infographic

solderic.com

solderic.com