Crystal oscillator soldering requires precise temperature control and minimal exposure time to prevent damage to the quartz element, unlike standard IC soldering, which typically tolerates a broader thermal range due to its semiconductor packaging. Understanding these critical differences can improve Your assembly quality and reliability; delve deeper into the article to master the best soldering practices.

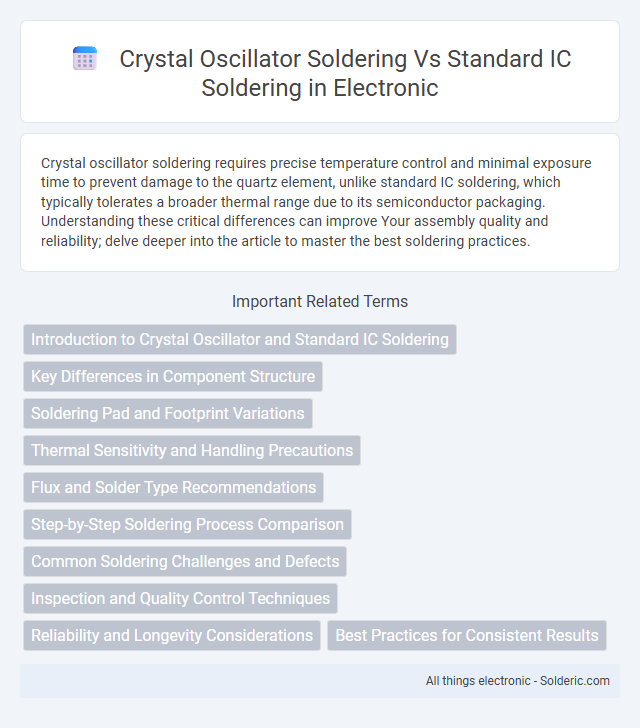

Comparison Table

| Aspect | Crystal Oscillator Soldering | Standard IC Soldering |

|---|---|---|

| Component Sensitivity | High sensitivity to heat and mechanical stress | Moderate heat tolerance, less sensitive to mechanical stress |

| Soldering Temperature | Typically 230degC - 260degC, short duration to prevent damage | Standard 240degC - 260degC, standard duration |

| Preheating | Recommended to reduce thermal shock | Optional or standard practice |

| Flux Type | Use of no-clean or mild flux to avoid crystal contamination | Standard no-clean flux commonly used |

| Mechanical Handling | Careful handling to avoid cracking crystal inside | Standard handling procedures apply |

| Reflow Profile | Modified profile with controlled ramp-up and peak to protect crystal | Standard reflow profile per IC datasheet |

| Inspection Focus | Check for solder joint quality and crystal cracking | Check for solder joint quality and component alignment |

Introduction to Crystal Oscillator and Standard IC Soldering

Crystal oscillator soldering demands precise thermal control and careful handling due to its sensitivity to heat and potential frequency drift, unlike standard IC soldering which generally tolerates higher temperatures and quicker processes. The unique quartz element inside crystal oscillators requires minimizing thermal stress to maintain accuracy, whereas standard ICs mostly involve semiconductor components that are more robust during soldering. Optimal soldering techniques for your crystal oscillator enhance device stability and prolong lifespan, ensuring reliable circuit performance.

Key Differences in Component Structure

Crystal oscillators feature a sealed quartz crystal encapsulated in a metal or ceramic package, designed to vibrate at precise frequencies, while standard ICs consist of silicon-based integrated circuits housed in plastic or ceramic packages. The internal structure of crystal oscillators includes a piezoelectric element essential for frequency stability, contrasting with the transistor and logic gate arrays found in ICs. Your soldering technique must accommodate the crystal oscillator's sensitivity to heat and mechanical stress compared to the generally robust nature of standard IC packages.

Soldering Pad and Footprint Variations

Crystal oscillator soldering requires specialized soldering pads and footprint designs that differ significantly from standard IC soldering to ensure optimal mechanical stability and electrical performance. Oscillator pads are often larger and more spaced to accommodate the quartz crystal's sensitivity and to minimize thermal stress, preventing frequency drift during operation. Footprint variations include distinct pad shapes and positions aligned with the crystal housing, improving heat dissipation and reducing parasitic capacitance compared to typical IC pads.

Thermal Sensitivity and Handling Precautions

Crystal oscillators exhibit higher thermal sensitivity compared to standard ICs, requiring precise temperature control during soldering to prevent damage or frequency drift. Handling precautions include minimizing exposure to heat by using lower soldering temperatures and shorter contact times, as well as employing specialized fixtures or heat sinks when necessary. Ensuring your soldering technique respects these constraints will maintain oscillator performance and reliability in your electronic circuits.

Flux and Solder Type Recommendations

For crystal oscillator soldering, use low-residue or no-clean flux to prevent contamination and potential frequency drift, while standard IC soldering typically tolerates rosin-based flux. Employ a solder alloy with a melting point around 183degC, like SAC305 (tin-silver-copper), ensuring compatibility with lead-free standards for both components. Precise temperature control and minimal heat exposure are critical to preserve the crystal's accuracy and avoid damage during soldering.

Step-by-Step Soldering Process Comparison

Crystal oscillator soldering requires precise temperature control and minimal heat exposure to preserve frequency accuracy, typically involving preheating the PCB, applying flux, and using a fine-tipped soldering iron to avoid thermal damage. Standard IC soldering generally follows a similar process but allows for higher temperature tolerance and longer soldering duration, often using reflow soldering or wave soldering techniques for mass production. Both processes demand careful pad alignment and solder joint inspection, though crystal oscillators need additional emphasis on minimizing mechanical stress to maintain stable oscillation.

Common Soldering Challenges and Defects

Crystal oscillator soldering often faces challenges such as heat sensitivity leading to internal damage, cold solder joints due to improper temperature control, and solder bridging caused by closely spaced pins. Standard IC soldering typically encounters issues like insufficient wetting, solder balling, and component misalignment, but these are less likely to cause functional failure compared to crystal oscillators. Ensuring precise temperature profiles and proper solder paste application can significantly improve Your soldering quality for both crystal oscillators and standard ICs.

Inspection and Quality Control Techniques

Crystal oscillator soldering demands meticulous inspection techniques due to its sensitivity to temperature variations and mechanical stress, requiring infrared thermography and X-ray inspection to detect solder joint integrity and voids. Standard IC soldering inspections typically rely on automated optical inspection (AOI) and electrical testing to ensure connectivity and function. Quality control in crystal oscillator soldering prioritizes vibration testing and resonance frequency verification to maintain oscillator performance, whereas standard IC quality control emphasizes functionality and electrical parameter validation.

Reliability and Longevity Considerations

Crystal oscillator soldering demands precise temperature control and minimal thermal stress to preserve the quartz crystal's frequency stability and extend its lifespan, unlike standard IC soldering which generally tolerates broader thermal profiles. The encapsulated nature and sensitivity of crystal oscillators mean improper soldering can induce mechanical stress, leading to frequency drift or outright failure over time. Ensuring optimal soldering conditions significantly enhances reliability and longevity, preventing degradation that standard ICs are less susceptible to under similar soldering processes.

Best Practices for Consistent Results

Crystal oscillator soldering requires precise temperature control between 230degC and 260degC to prevent damage to the delicate quartz element, whereas standard IC soldering typically tolerates slightly higher temperatures up to 260degC. Using a soldering iron with a fine tip and minimal dwell time under 5 seconds enhances joint quality and prevents thermal stress in crystal oscillators, while standard ICs benefit from slightly longer soldering times for secure connections. Applying flux sparingly and ensuring proper pad cleanliness are essential best practices for both components to achieve reliable and consistent solder joints.

Crystal oscillator soldering vs standard IC soldering Infographic

solderic.com

solderic.com