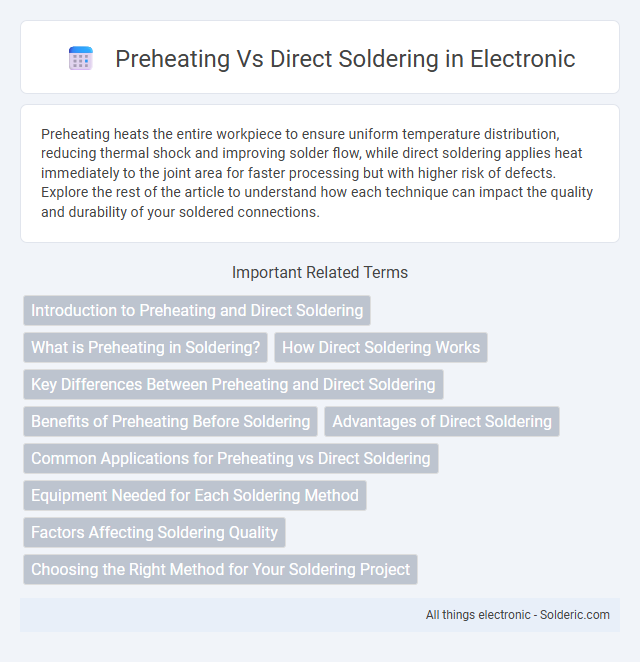

Preheating heats the entire workpiece to ensure uniform temperature distribution, reducing thermal shock and improving solder flow, while direct soldering applies heat immediately to the joint area for faster processing but with higher risk of defects. Explore the rest of the article to understand how each technique can impact the quality and durability of your soldered connections.

Comparison Table

| Aspect | Preheating | Direct Soldering |

|---|---|---|

| Definition | Gradual heating of components to minimize thermal shock before soldering | Applying solder directly to components without prior heating |

| Temperature Control | Controlled ramp-up to target temperature | Immediate exposure to soldering temperature |

| Thermal Stress | Reduces risk of thermal shock and component damage | Higher risk of thermal shock and possible component damage |

| Application | Used in sensitive electronic components and multilayer PCBs | Suitable for robust components with high thermal tolerance |

| Quality | Improves solder joint reliability and consistency | May result in uneven solder joints and defects |

| Process Time | Longer due to heating phase | Shorter, single-step process |

Introduction to Preheating and Direct Soldering

Preheating involves gradually raising the temperature of a component or circuit board before applying solder, which helps reduce thermal shock and ensures even heat distribution. Direct soldering applies heat immediately to the solder joint, enabling faster processing but increasing the risk of component damage. Understanding the differences between these methods allows you to choose the optimal soldering technique for your specific electronic assembly needs.

What is Preheating in Soldering?

Preheating in soldering refers to the controlled warming of a component or PCB before the actual soldering process to reduce thermal shock and improve solder flow. This step enhances joint reliability by minimizing the risk of defects such as cold solder joints and warpage. Effective preheating typically involves raising the substrate temperature to 100-150degC depending on the materials involved.

How Direct Soldering Works

Direct soldering involves applying the soldering iron or heat source directly to the joint without preheating the components or board. This method relies on rapid heat transfer to melt the solder and create a strong bond quickly while minimizing thermal stress to nearby components. Your complete understanding of direct soldering enables precise control over temperature and timing to achieve optimal solder joints.

Key Differences Between Preheating and Direct Soldering

Preheating involves gradually raising the temperature of a component or PCB to reduce thermal stress before applying solder, while direct soldering applies heat and solder directly without prior warming. Preheating improves joint reliability and reduces the risk of component damage or warping, making it essential for temperature-sensitive materials. Your choice between methods depends on component specifications, thermal mass, and the desired quality of solder joints.

Benefits of Preheating Before Soldering

Preheating before soldering improves solder joint quality by promoting even heat distribution and reducing thermal shock to sensitive components. It enhances solder flow and wetting, resulting in stronger, more reliable connections while minimizing the risk of board warping or component damage. You can achieve higher production yields and reduce rework costs by incorporating preheating into your soldering process.

Advantages of Direct Soldering

Direct soldering offers faster processing times by eliminating the need for preheating, increasing overall production efficiency. This method reduces energy consumption and lowers operational costs due to simplified workstation setup and fewer heating cycles. Additionally, direct soldering minimizes thermal stress on components, enhancing reliability and quality in sensitive electronic assemblies.

Common Applications for Preheating vs Direct Soldering

Preheating is commonly applied in sensitive electronics and complex assemblies to prevent thermal shock and ensure uniform heat distribution, particularly in surface-mount technology and multi-layer circuit boards. Direct soldering suits straightforward tasks like simple wire connections or through-hole components where rapid heating suffices without risking component damage. Your choice between these methods depends on the materials involved and the thermal sensitivity of the components.

Equipment Needed for Each Soldering Method

Preheating soldering requires equipment such as a temperature-controlled preheating station or hotplate to evenly warm the entire PCB before soldering, ensuring consistent thermal distribution and preventing thermal shock. Direct soldering involves tools like soldering irons or hot air rework stations, often paired with flux applicators and solder wire for precise, localized heating without the need for preheating the substrate. Both methods may utilize thermal profiling tools to monitor temperature accuracy, but preheating demands more extensive setup to maintain optimal preheat temperatures.

Factors Affecting Soldering Quality

Preheating influences soldering quality by reducing thermal shock and promoting uniform heat distribution, which minimizes defects such as cold joints and warping. Direct soldering relies on immediate heat application but can increase the risk of insufficient solder flow and component damage due to rapid temperature changes. Your soldering process must balance these factors, considering component materials, PCB design, and thermal profiles to ensure reliable joints and overall product integrity.

Choosing the Right Method for Your Soldering Project

Preheating stabilizes the entire assembly, reducing thermal shock and improving solder joint quality, especially for complex or heat-sensitive components. Direct soldering delivers rapid, localized heat, making it suitable for quick repairs or simple projects where precision is paramount. Selecting the right method for your soldering project depends on component type, thermal tolerance, and desired reliability, ensuring optimal performance and durability.

Preheating vs direct soldering Infographic

solderic.com

solderic.com