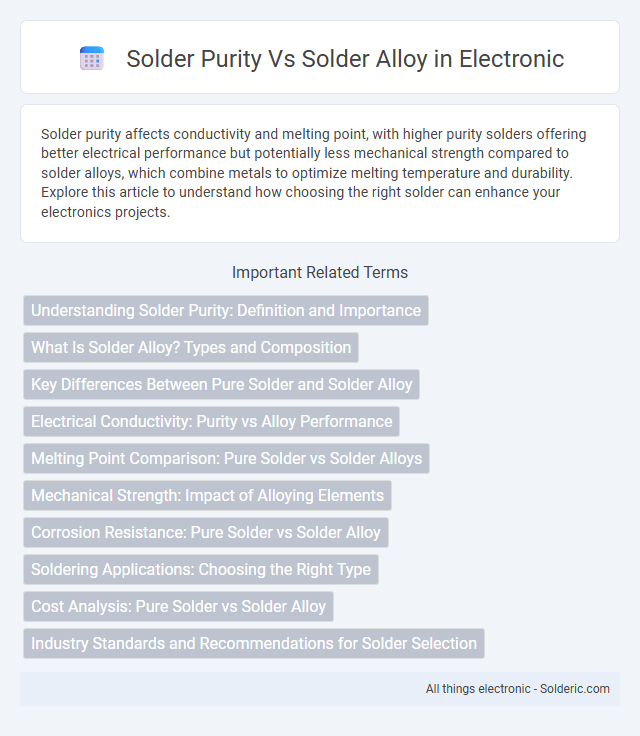

Solder purity affects conductivity and melting point, with higher purity solders offering better electrical performance but potentially less mechanical strength compared to solder alloys, which combine metals to optimize melting temperature and durability. Explore this article to understand how choosing the right solder can enhance your electronics projects.

Comparison Table

| Aspect | Solder Purity | Solder Alloy |

|---|---|---|

| Definition | Level of pure metal content in solder | Combination of metals forming solder with specific properties |

| Composition | Predominantly single metal (e.g., Tin 99.9%) | Multiple metals (e.g., Tin-Lead, Tin-Silver-Copper) |

| Melting Point | Higher and narrow melting range | Lower and broader melting range (eutectic or near-eutectic) |

| Mechanical Strength | Lower, brittle | Higher, improved durability |

| Electrical Conductivity | Generally higher due to purity | Slightly reduced but optimized for performance |

| Typical Use | Specialized applications needing high purity | Most electronics and general soldering |

| Cost | Higher due to refining | Lower, cost-effective for mass production |

Understanding Solder Purity: Definition and Importance

Solder purity refers to the proportion of the base metals in the solder alloy that are free from contaminants or impurities, directly impacting joint strength and electrical conductivity. High-purity solder ensures better thermal and mechanical properties, reducing defects such as brittle joints or poor wettability. Understanding your solder's purity is crucial for achieving reliable and durable electronic connections, especially in sensitive or high-performance applications.

What Is Solder Alloy? Types and Composition

Solder alloy is a combination of two or more metals fused to create a material with improved mechanical and electrical properties for joining components. Common solder alloys include tin-lead (Sn-Pb), lead-free options like tin-silver-copper (SAC), and specialty variants with bismuth or indium, each offering distinct melting points and conductivity. Understanding your solder alloy composition ensures optimal performance and reliability in electronic or plumbing applications.

Key Differences Between Pure Solder and Solder Alloy

Pure solder consists primarily of a single metal, usually tin, offering simplicity and high conductivity but limited mechanical strength. Solder alloys combine metals like tin, lead, silver, or copper to enhance properties such as melting point, tensile strength, and corrosion resistance. Understanding these key differences helps you select the ideal solder for specific electronics or plumbing applications, balancing performance and durability.

Electrical Conductivity: Purity vs Alloy Performance

Solder purity directly impacts electrical conductivity, with higher-purity solders typically offering lower electrical resistance and enhanced signal transmission. Alloy solders, while potentially lower in purity, balance conductivity with mechanical strength and thermal reliability, often outperforming pure solders in practical electronic applications. Optimizing solder composition involves trade-offs between maximizing electrical performance and ensuring durable, stable connections under varying operating conditions.

Melting Point Comparison: Pure Solder vs Solder Alloys

Pure solder, typically composed of 99.3% tin and 0.7% copper, has a melting point around 227degC (441degF), providing a consistent and predictable melting behavior. Solder alloys, such as tin-lead (63/37) or lead-free options like SAC305 (tin-silver-copper), exhibit melting points that range between 183degC to 217degC depending on the specific composition, often featuring a melting range rather than a sharp melting point due to the alloy's microstructure. Understanding the melting point differences helps you select the right solder for precision in electronic soldering tasks and optimal joint reliability.

Mechanical Strength: Impact of Alloying Elements

Solder purity significantly affects mechanical strength, with alloying elements like silver, copper, and tin enhancing joint robustness and thermal fatigue resistance. Pure solder offers high conductivity but lacks the mechanical stability provided by these added metals, which improve tensile strength and fracture toughness. Your choice of solder alloy directly influences the durability and reliability of electronic assemblies under mechanical stress.

Corrosion Resistance: Pure Solder vs Solder Alloy

Pure solder typically offers higher corrosion resistance due to its uniform composition, reducing the risk of galvanic corrosion in electronic joints. Solder alloys, containing metals like tin, lead, or silver, may exhibit varied corrosion resistance depending on their specific elemental makeup and environmental exposure. When selecting solder for your project, consider the application environment to balance corrosion resistance and mechanical strength, often favoring pure solder for sensitive electronics requiring longevity.

Soldering Applications: Choosing the Right Type

Solder purity directly impacts the strength and conductivity of solder joints in various applications, while solder alloys offer tailored melting points and mechanical properties to suit specific tasks. Your choice between pure solder and solder alloy depends on the application's requirements, such as electrical conductivity, thermal resistance, and mechanical durability. Understanding these properties ensures optimal performance and reliability in electronic assembly or plumbing projects.

Cost Analysis: Pure Solder vs Solder Alloy

Pure solder typically incurs higher costs due to the use of expensive, refined materials like 99.9% pure tin or silver. Solder alloys, composed of combinations such as tin-lead, tin-silver-copper (SAC), or tin-copper, offer cost-effective alternatives by balancing performance with lower material expenses. When conducting cost analysis, solder alloys provide a more economical solution for large-scale manufacturing without compromising reliability in most electronic assembly applications.

Industry Standards and Recommendations for Solder Selection

Industry standards such as IPC J-STD-006 and J-STD-001 provide detailed guidelines on solder purity and alloy compositions to ensure reliable electronic assemblies. High-purity solders, typically with a minimum of 99.3% tin content, are recommended for minimizing defects like voids and improving wettability, while alloy choices like SAC305 (Tin-Silver-Copper) balance mechanical strength and thermal fatigue resistance. Selecting solder alloys compliant with these standardized specifications directly impacts joint integrity and long-term performance in automotive, aerospace, and consumer electronics industries.

Solder purity vs solder alloy Infographic

solderic.com

solderic.com