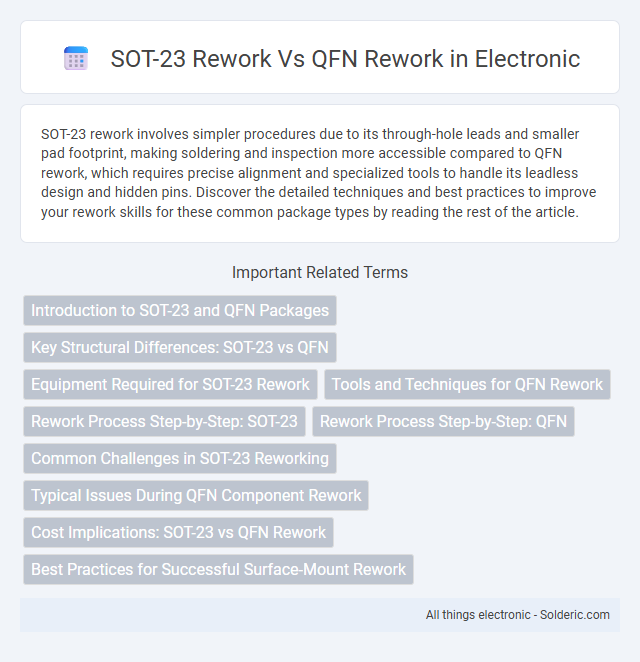

SOT-23 rework involves simpler procedures due to its through-hole leads and smaller pad footprint, making soldering and inspection more accessible compared to QFN rework, which requires precise alignment and specialized tools to handle its leadless design and hidden pins. Discover the detailed techniques and best practices to improve your rework skills for these common package types by reading the rest of the article.

Comparison Table

| Feature | SOT-23 Rework | QFN Rework |

|---|---|---|

| Package Type | Small Outline Transistor, 3 pins | Quad Flat No-Lead, multiple pins |

| Pin Accessibility | Leads exposed, easy to access | Leads underneath, difficult to access |

| Heat Sensitivity | Moderate, heat evenly distributed | High, risk of thermal damage |

| Tools Required | Hot air rework station, soldering iron | Hot air rework station, infrared heater, specialized PCB holder |

| Inspection Ease | Simple visual inspection | Requires X-ray or microscope |

| Rework Complexity | Low, straightforward process | High, requires skill and precision |

| Common Applications | Discrete transistors, small ICs | High-density ICs, advanced packaging |

| Cost Implications | Lower labor and tool costs | Higher due to complexity and equipment |

Introduction to SOT-23 and QFN Packages

SOT-23 and QFN packages are widely used surface-mount device encapsulations in electronics manufacturing, each offering distinct mechanical and thermal characteristics. SOT-23 packages are small, three-lead plastic encapsulated transistors or diodes known for ease of rework due to their exposed leads and simple structure. QFN packages, featuring a flat, leadless design with pads underneath, provide excellent electrical performance and thermal dissipation but demand more precise rework techniques to avoid damage during your repair or modification processes.

Key Structural Differences: SOT-23 vs QFN

SOT-23 packages feature a small, three-lead plastic surface-mount design with exposed leads bent outward for easy soldering, while QFN packages have a flat, leadless design with terminations beneath the component, offering better thermal and electrical performance. The SOT-23's visible leads simplify manual rework and inspection, whereas the QFN requires precise alignment and often specialized equipment due to its hidden contacts. Understanding these structural differences is crucial for optimizing your rework approach, as QFN repairs demand greater care and technique compared to the more straightforward SOT-23 process.

Equipment Required for SOT-23 Rework

SOT-23 rework requires precision tools such as a fine-tip soldering iron, hot air rework station with adjustable airflow, and magnification equipment for accurate component placement. Proper ESD-safe tweezers and solder wick or desoldering braid are essential for efficient solder removal. A temperature-controlled PCB holder and flux are recommended to ensure thermal stability and reliable solder joints during the rework process.

Tools and Techniques for QFN Rework

QFN rework requires specialized tools such as hot air rework stations with precise temperature control, vacuum pickup tools, and flux dispensers to ensure uniform heating and reliable solder joint formation. Techniques include controlled preheating to prevent thermal stress, use of solder paste inspection systems for accurate placement, and careful alignment using X-ray or optical inspection to maintain electrical integrity. Unlike SOT-23 rework, QFN packages demand meticulous underfill handling and pad cleaning to avoid solder voids and ensure long-term reliability.

Rework Process Step-by-Step: SOT-23

The SOT-23 rework process begins with careful desoldering using a hot air tool to avoid damaging the small leads and surrounding PCB. Precise cleaning of pads with flux and solder wick ensures proper surface preparation before placement of the new component. Controlled reheating and soldering solidify the connections, preserving the integrity of your PCB and ensuring reliable electrical contact.

Rework Process Step-by-Step: QFN

The QFN rework process involves precise solder paste application, careful nozzle placement for component removal using a hot air rework station, and meticulous PCB pad cleaning to prevent bridging or pad lifting. You must carefully align the replacement QFN component, ensuring proper thermal profile adherence during reflow to guarantee optimal solder joint integrity. Final inspection with X-ray or AOI ensures that solder joints meet quality standards, minimizing defects common in fine-pitch QFN packages.

Common Challenges in SOT-23 Reworking

SOT-23 rework often involves challenges such as small pad sizes, limited access to leads, and the risk of thermal damage to sensitive semiconductor components. Precise soldering techniques and specialized tools are required to avoid lifting pads or causing solder bridging, which are common issues due to the compact footprint. Your rework process should emphasize careful temperature control and fine-tip soldering to ensure component integrity and reliable electrical connections.

Typical Issues During QFN Component Rework

Typical issues during QFN component rework include solder joint bridging, solder voids, and pad damage due to the hidden nature of the QFN pads underneath the component. Heat distribution challenges arise because QFNs have an exposed thermal pad that requires precise temperature control to avoid warping or delamination. In contrast, SOT-23 rework is less complex due to visible leads and lower thermal mass, reducing the risk of thermal damage and simplifying defect detection.

Cost Implications: SOT-23 vs QFN Rework

Reworking SOT-23 packages generally incurs lower costs due to their simpler structure and easier accessibility compared to QFN packages, which require more specialized tools and techniques to handle their hidden solder joints. The cost of QFN rework escalates with the need for precise thermal profiling and underfill removal, increasing labor and equipment expenses. Your choice between SOT-23 and QFN rework should consider these cost differences alongside the complexity of the PCB layout and component density.

Best Practices for Successful Surface-Mount Rework

For successful surface-mount rework, SOT-23 packages require precise temperature control and minimal heat exposure due to their small size and lead configuration, ensuring solder joints are reflowed without damaging the component or PCB pads. QFN rework demands careful preheating and specialized tooling like vacuum pickup and hot air or infrared reflow stations to access the hidden thermal pads and prevent solder voids while maintaining uniform heat distribution. Accurate alignment, flux application, and temperature profiling tailored to each package type optimize rework quality and reliability in high-density PCB assemblies.

SOT-23 rework vs QFN rework Infographic

solderic.com

solderic.com