The T12 tip and 900M tip are two popular soldering iron tips, each designed for different applications; the T12 tip offers faster heating and better thermal conductivity, ideal for precision electronics work, while the 900M tip is more traditional and versatile, suitable for general-purpose soldering tasks. Explore the rest of the article to determine which tip best suits your soldering needs and enhances your project's efficiency.

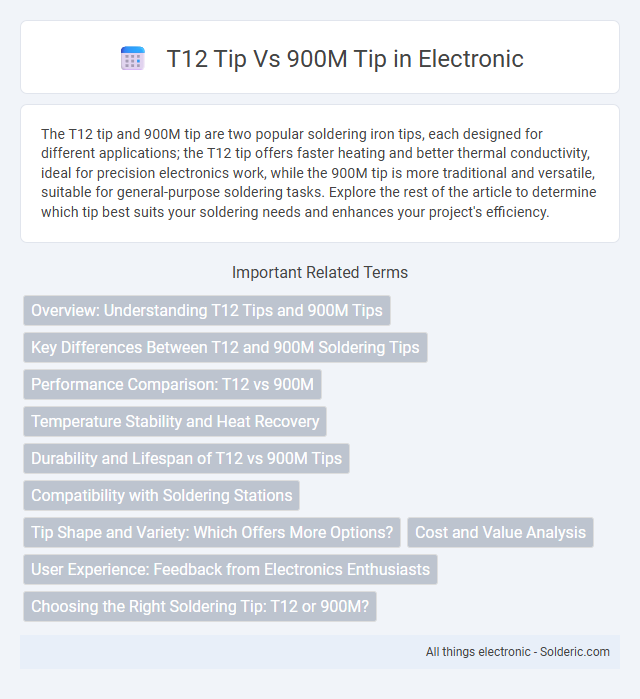

Comparison Table

| Feature | T12 Tip | 900M Tip |

|---|---|---|

| Compatibility | T12 soldering stations (e.g. Aoyue, Quick) | Weller WSD81, WES51, and compatible models |

| Tip Shape Variety | Wide range: conical, chisel, bevel | Fewer shapes, mainly chisel |

| Heating Technology | Inductive heating with integrated element | Resistive heating element |

| Heating Time | Quick heat-up (~10 seconds) | Slower heat-up (~30 seconds) |

| Temperature Stability | High stability with PID control | Moderate stability |

| Tip Longevity | Long-lasting plating, easy to replace | Standard longevity, replaceable |

| Cost | Affordable, budget-friendly | Generally more expensive |

| Usage | Electronics soldering, fine detail work | General electronics repair |

Overview: Understanding T12 Tips and 900M Tips

T12 tips and 900M tips are popular soldering iron tips designed for precision and durability, each suited for different soldering tasks. T12 tips are known for their rapid heat-up and excellent temperature stability due to their ceramic heater technology, making them ideal for fine electronics work. In contrast, 900M tips feature a more traditional design with copper cores plated in iron, offering versatility and compatibility with a wide range of soldering irons but with slower heat retention compared to T12 tips.

Key Differences Between T12 and 900M Soldering Tips

T12 soldering tips feature rapid heating and precise temperature control, making them ideal for delicate electronics work, while 900M tips offer robust durability and higher heat capacity suitable for heavy-duty soldering tasks. The T12's ceramic heater design ensures consistent thermal performance with minimal temperature fluctuation, whereas the 900M tips rely on a traditional metallic heating element, resulting in slower recovery times. Your choice between T12 and 900M tips should depend on the required precision and soldering speed for your specific applications.

Performance Comparison: T12 vs 900M

The T12 tip offers faster heat-up times and more precise temperature control compared to the 900M tip, making it ideal for delicate soldering tasks. Its advanced thermal recovery ensures consistent heat delivery, reducing the risk of damage to sensitive components. While the 900M tip provides robust durability for general purpose soldering, the T12 tip outperforms in efficiency and accuracy for high-precision electronics work.

Temperature Stability and Heat Recovery

The T12 tip offers superior temperature stability due to its enhanced internal heating element, maintaining consistent heat throughout soldering tasks. Compared to the 900M tip, the T12 tip also excels in heat recovery, allowing faster return to optimal temperature after contact with components. Your soldering efficiency improves significantly with the T12 tip's precise thermal management, reducing cooldown times and ensuring reliable joints.

Durability and Lifespan of T12 vs 900M Tips

T12 tips exhibit superior durability due to their robust ceramic heating elements, allowing for prolonged use without degradation compared to 900M tips. The 900M tips, often made with thinner metal components, wear out faster under high-temperature soldering conditions, reducing their overall lifespan. Consequently, T12 tips provide extended operational longevity, translating to cost-effective and consistent performance in professional soldering applications.

Compatibility with Soldering Stations

The T12 tip offers wide compatibility with many popular soldering stations, such as those from Hakko, making it a versatile choice for diverse electronic projects. The 900M tip typically fits soldering irons designed specifically for older or less common models, limiting its interchangeability compared to the T12. When selecting your soldering station, consider the tip's compatibility to ensure optimal performance and easy replacement.

Tip Shape and Variety: Which Offers More Options?

T12 tips feature a slim, chisel-shaped design ideal for precise soldering in electronics, while 900M tips offer a broader variety of shapes, including conical, chisel, and knife styles, catering to diverse soldering tasks. The 900M series provides more options, making it suitable for users needing adaptability across different projects. Choosing Your soldering iron tip depends on task specificity, with 900M tips enhancing flexibility through their wider shape selection.

Cost and Value Analysis

The T12 tip offers a cost-effective solution with a longer lifespan and better energy efficiency compared to the 900M tip, making it more economical for frequent soldering tasks. While the 900M tip provides precise control and is preferred for delicate electronics work, it typically costs more and wears out faster under heavy use. Evaluating the price-per-use ratio, the T12 tip delivers superior value for professionals prioritizing durability and cost savings.

User Experience: Feedback from Electronics Enthusiasts

Electronics enthusiasts report that T12 tips offer superior thermal recovery and precision, enhancing soldering accuracy for intricate components. The 900M tips, favored for their versatility and durability, provide consistent heat transfer but may lack the fine control required for ultra-fine work. User feedback highlights T12 tips as the preferred choice for detailed tasks, while 900M tips suit general-purpose soldering with robust performance.

Choosing the Right Soldering Tip: T12 or 900M?

T12 soldering tips offer faster heat recovery and improved temperature stability compared to 900M tips, making them ideal for precision electronics soldering. The 900M tips, while more affordable and widely available, tend to have slower heat-up times and less consistent temperature control. Choosing the right soldering tip depends on your project's complexity and precision needs, where T12 tips enhance efficiency and accuracy for demanding tasks.

T12 tip vs 900M tip Infographic

solderic.com

solderic.com