Wound core transformers offer superior magnetic efficiency and reduced noise compared to laminated core transformers, making them ideal for applications requiring minimal energy loss and compact design. Explore the rest of the article to understand which transformer type best suits Your specific needs and operational environment.

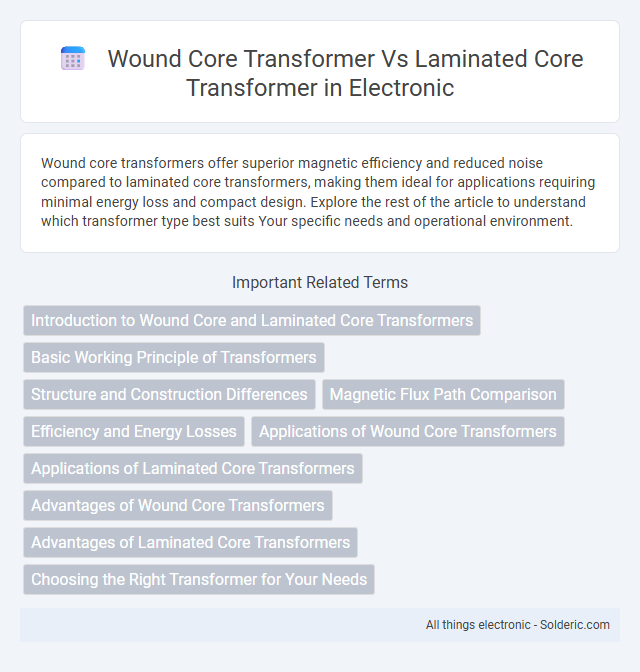

Comparison Table

| Feature | Wound Core Transformer | Laminated Core Transformer |

|---|---|---|

| Core Construction | Wound core made from insulated copper or aluminum windings | Built from stacked, insulated silicon steel laminations |

| Magnetic Losses | Lower eddy current losses due to winding structure | Reduced eddy current losses by laminations but higher than wound core |

| Frequency Range | Ideal for high-frequency applications | Commonly used in low-frequency, power distribution transformers |

| Efficiency | Higher efficiency at high frequencies | Efficient at low frequencies but less so at high frequencies |

| Manufacturing Complexity | More complex winding process | Simpler stacking and assembly process |

| Cost | Generally higher due to winding process | Lower cost, widely used in power transformers |

| Applications | High-frequency transformers, RF transformers, audio transformers | Power transformers, distribution transformers, industrial transformers |

| Noise Level | Lower noise due to compact winding | Higher audible noise from lamination vibrations |

Introduction to Wound Core and Laminated Core Transformers

Wound core transformers use a cylindrical core made by winding thin strips of silicon steel, which reduces eddy current losses and improves magnetic efficiency. Laminated core transformers consist of stacked thin steel sheets insulated from each other to minimize eddy currents while enhancing performance and durability. Your choice between these transformer types depends on factors like efficiency, noise level, and application requirements.

Basic Working Principle of Transformers

Wound core transformers utilize continuous windings around a ring-shaped core made of grain-oriented silicon steel to reduce eddy current losses and improve efficiency. Laminated core transformers consist of stacked thin steel sheets insulated from each other, minimizing eddy currents by restricting their flow within each lamination. Both designs operate on the principle of electromagnetic induction, where an alternating current in the primary winding generates a varying magnetic flux that induces voltage in the secondary winding.

Structure and Construction Differences

Wound core transformers feature a core constructed by winding thin magnetic strips into a coil, resulting in a spiral structure that reduces eddy current losses and improves flux leakage control. Laminated core transformers have cores made from stacked, insulated steel sheets, which enhance magnetic efficiency by minimizing eddy currents while providing mechanical stability. The wound core design generally offers better noise reduction and higher permeability, whereas laminated cores are easier to manufacture for standard power applications.

Magnetic Flux Path Comparison

Wound core transformers feature a continuous magnetic flux path created by wound grain-oriented silicon steel strips, resulting in reduced flux leakage and lower core losses compared to laminated core transformers. Laminated core transformers utilize stacked thin steel sheets insulated from each other to minimize eddy current losses, but the segmented construction creates more flux leakage points along the magnetic path. The continuous, closed-loop design of wound cores enhances magnetic coupling efficiency, making them superior for applications requiring low noise and high performance in the magnetic flux path.

Efficiency and Energy Losses

Wound core transformers typically exhibit lower core losses due to their continuous magnetic path and reduced air gaps, resulting in higher efficiency compared to laminated core transformers. Laminated core transformers experience increased eddy current losses caused by the discrete layers of steel laminations, which can reduce overall efficiency, especially at higher frequencies. Both types aim to minimize hysteresis and eddy current losses, but wound core designs excel in applications demanding minimal energy losses and enhanced efficiency.

Applications of Wound Core Transformers

Wound core transformers excel in applications requiring low noise and efficient magnetic flux control, such as audio equipment, medical devices, and precision instrumentation. Their continuous magnetic path reduces eddy current losses, making them ideal for sensitive environments and high-frequency use. You can rely on wound core transformers for enhanced performance in specialized and noise-sensitive electrical systems.

Applications of Laminated Core Transformers

Laminated core transformers are widely used in electrical distribution systems, power supplies, and audio devices due to their efficiency in reducing eddy current losses. Their construction with thin steel laminations enables effective magnetic flux conduction while minimizing energy dissipation, making them ideal for lower frequency applications such as power transformers in residential and industrial settings. These transformers are commonly found in voltage regulation, isolation, and step-down applications where durability and energy efficiency are crucial.

Advantages of Wound Core Transformers

Wound core transformers offer superior magnetic flux control due to their continuously wound coils, which reduce leakage inductance and enhance overall efficiency. Their design minimizes noise and vibration, making them ideal for sensitive applications requiring quiet operation. You benefit from better thermal management and lower iron losses compared to laminated core transformers, resulting in improved performance and longevity.

Advantages of Laminated Core Transformers

Laminated core transformers offer superior efficiency due to reduced eddy current losses compared to wound core transformers, enhancing energy savings in electrical systems. The use of thin, insulated steel laminations minimizes hysteresis losses, allowing for better magnetic flux conduction and improved performance under variable loads. Your choice of laminated core transformers ensures durability and quieter operation, making them ideal for applications demanding consistent power quality and lower maintenance.

Choosing the Right Transformer for Your Needs

Wound core transformers utilize continuous copper windings around a magnetic core, offering superior high-frequency performance and reduced core losses compared to laminated core transformers, which consist of stacked silicon steel sheets to minimize eddy currents. Selecting a wound core transformer benefits applications requiring low noise, compact size, and efficient energy transfer at higher frequencies, while laminated core transformers are ideal for power distribution with better mechanical strength and cost-effectiveness in low-frequency settings. Understanding your operational frequency, noise sensitivity, and efficiency requirements is essential when choosing between wound core and laminated core transformers.

wound core transformer vs laminated core transformer Infographic

solderic.com

solderic.com