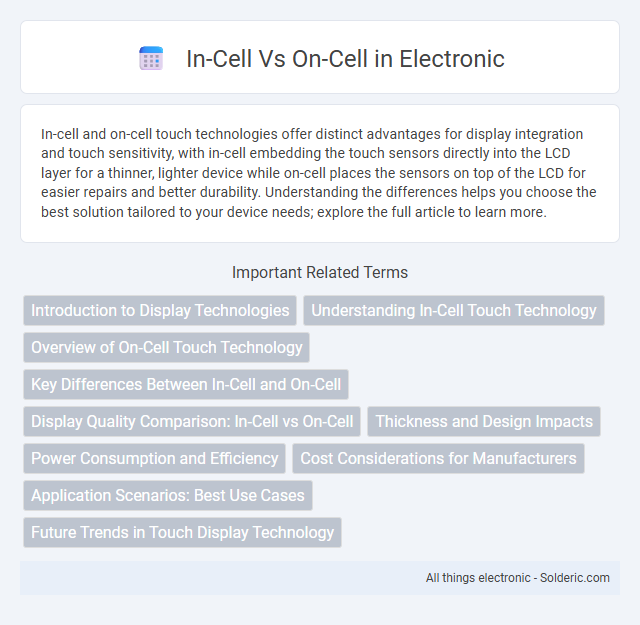

In-cell and on-cell touch technologies offer distinct advantages for display integration and touch sensitivity, with in-cell embedding the touch sensors directly into the LCD layer for a thinner, lighter device while on-cell places the sensors on top of the LCD for easier repairs and better durability. Understanding the differences helps you choose the best solution tailored to your device needs; explore the full article to learn more.

Comparison Table

| Feature | In-Cell | On-Cell |

|---|---|---|

| Definition | Fingerprint sensor integrated beneath the display glass | Fingerprint sensor placed directly on top of the display surface |

| Installation | Embedded within the screen layers | Attached externally on the display panel |

| Design Impact | Sleek, seamless display without extra sensor area | Visible sensor area, slightly interrupting display continuity |

| Durability | Protected by screen glass, less prone to damage | Exposed sensor can be more vulnerable to wear and tear |

| Fingerprint Reading Speed | Generally slower due to sensor behind glass | Typically faster as sensor has direct contact |

| Accuracy | High accuracy with advanced optical or ultrasonic tech | High accuracy but dependent on sensor quality |

| Cost | Higher production cost due to integration technology | Lower cost, simpler installation |

| Use Cases | Flagship smartphones, premium devices | Mid-range devices, models prioritizing cost |

Introduction to Display Technologies

In-cell and on-cell display technologies differ primarily in how touch sensors are integrated within a screen, impacting thickness, clarity, and production costs. In-cell touch integrates sensors directly into the LCD layers, resulting in thinner displays and enhanced touch responsiveness, while on-cell places sensors on top of the LCD, offering easier repairs and potentially lower manufacturing complexity. Choosing the right technology affects your device's display performance and overall user experience, balancing responsiveness with durability.

Understanding In-Cell Touch Technology

In-Cell touch technology integrates the touch sensor directly within the LCD panel, reducing screen thickness and improving touch responsiveness compared to traditional On-Cell designs, where the sensor is a separate layer placed on top of the display. This integration enhances display clarity and reduces glare by minimizing the number of layers between your finger and the screen. Understanding these differences can help you select devices with better touch sensitivity and improved overall user experience.

Overview of On-Cell Touch Technology

On-cell touch technology integrates the touch sensor directly on top of the LCD panel, creating a thinner display module compared to separate touch layers. It offers improved display clarity and reduced manufacturing costs by eliminating additional glass layers found in in-cell touch technology. On-cell touch is commonly used in mid-range smartphones and tablets, balancing performance and affordability.

Key Differences Between In-Cell and On-Cell

In-cell touch technology integrates touch sensors directly into the LCD panel, resulting in a slimmer display and improved optical clarity by reducing layers between the screen and user. On-cell touch technology places the touch sensors on top of the LCD, allowing easier manufacturing and repair but often leading to a slightly thicker display and less vibrant visuals. Both technologies impact device thinness, touch sensitivity, and display quality, making the choice dependent on design priorities and production costs.

Display Quality Comparison: In-Cell vs On-Cell

In-cell and on-cell touch technologies differ significantly in display quality, with in-cell touch integrating touch sensors directly into the LCD layers, resulting in thinner display panels and reduced light reflection that enhances brightness and clarity. On-cell displays position the touch sensor atop the LCD layer, which can cause slightly increased glare and marginally lower contrast due to the additional material layer. Consequently, in-cell displays generally offer superior optical performance with higher luminance and better color reproduction compared to on-cell displays.

Thickness and Design Impacts

In-cell display technology integrates touch sensors directly into the LCD layers, resulting in thinner screens and lighter devices compared to on-cell technology, which places touch sensors on top of the display. The reduced thickness of in-cell designs enhances overall device slimness and improves visual clarity by minimizing air gaps between layers, leading to better touch responsiveness and display quality. You benefit from more sleek and responsive devices with in-cell technology, while on-cell designs may offer easier manufacturing flexibility but at the cost of increased thickness.

Power Consumption and Efficiency

In-cell touch technology integrates touch sensors directly into the LCD layer, reducing power consumption by eliminating the need for a separate touch layer, which enhances overall display efficiency. On-cell technology places the touch sensor on top of the LCD, leading to slightly higher power usage due to additional components but allows for easier repairs and replacements. Your choice between in-cell and on-cell can impact battery life and device performance, making in-cell more suitable for power-sensitive applications.

Cost Considerations for Manufacturers

In-cell touch technology generally reduces manufacturing costs by integrating touch sensors directly into the LCD display, minimizing component count and assembly complexity. On-cell touch panels require a separate touch sensor layer placed above the display, increasing material expenses and assembly time for manufacturers. Choosing in-cell technology often results in slimmer device profiles and lower production costs, appealing to cost-conscious manufacturers aiming for high-volume production.

Application Scenarios: Best Use Cases

In-cell touch technology is ideal for smartphones and tablets requiring ultra-thin displays with excellent optical clarity and sensitivity, making it suitable for high-end mobile devices where space saving is critical. On-cell touch technology works best in larger displays like monitors, automotive screens, and industrial equipment due to its easier repairability and lower manufacturing cost. Your choice depends on factor priorities such as device size, durability, and cost-effectiveness in the intended application scenario.

Future Trends in Touch Display Technology

In-cell touch technology integrates touch sensors directly within the LCD layers, enabling slimmer displays and improved touch responsiveness, which is driving its adoption in smartphones and tablets. On-cell touch technology places the touch sensors on top of the LCD panel, offering ease of manufacturing and lower costs, making it suitable for devices where durability and budget are priorities. Future trends indicate a shift towards in-cell solutions combined with advanced AI-driven touch recognition and increased use of flexible OLED displays, enhancing user experience through more immersive and responsive interfaces.

In-Cell vs On-Cell Infographic

solderic.com

solderic.com