PCB rework focuses on modifying or correcting specific components on a printed circuit board during the manufacturing process to ensure functionality, while PCB repair involves fixing damaged or faulty boards after use to restore them to working condition. Understanding these differences can help you choose the right approach for your electronic projects--continue reading to explore the key distinctions and applications.

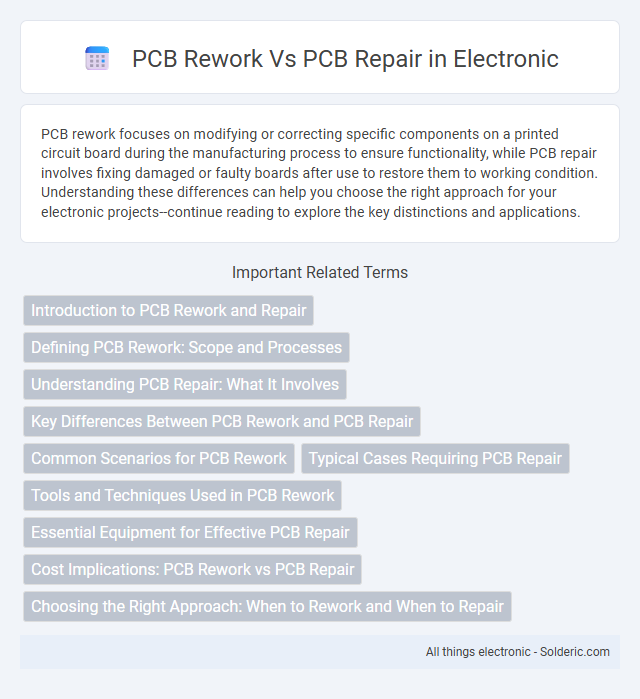

Comparison Table

| Aspect | PCB Rework | PCB Repair |

|---|---|---|

| Definition | Modification or correction of PCB components during production or post-assembly. | Restoration of damaged PCB areas or components to working condition. |

| Purpose | Correct assembly errors, replace faulty components, or upgrade functionality. | Fix physical damage, such as broken traces, pads, or burnt areas. |

| Process | Desoldering and resoldering components using reflow or hot air tools. | Repairing tracks, pads, vias, and substrate using specialized tools and materials. |

| Complexity | Moderate; focused on component-level changes. | Higher; involves structural PCB restoration. |

| Typical Tools | Hot air stations, soldering irons, rework stations. | Microscopes, PCB track repair kits, conductive ink, UV cure systems. |

| Common Use Cases | Component replacements, solder joint fixes, minor modifications. | Damaged copper traces, pad lifts, substrate cracks. |

| Cost Implication | Lower cost compared to full repair; quick corrections. | Higher cost due to complexity and materials required. |

| Outcome Reliability | High if performed correctly, especially during manufacturing. | Variable; depends on extent of damage and repair quality. |

Introduction to PCB Rework and Repair

PCB rework involves modifying or correcting a printed circuit board by removing and replacing specific components to ensure proper functionality, often using precise tools like soldering irons and hot air stations. PCB repair refers to fixing defects such as broken traces, damaged pads, or faulty components to restore the board's original operation without extensive modifications. Both processes are essential in electronics manufacturing and maintenance to enhance product reliability and extend the lifespan of circuit boards.

Defining PCB Rework: Scope and Processes

PCB rework involves the precise removal and replacement of defective components on a printed circuit board, covering processes such as soldering, desoldering, and component repositioning to restore functionality without redesigning the board. This scope targets localized corrections on surface mount devices (SMDs) and through-hole components, ensuring minimal disruption to the PCB layout and circuitry. Advanced techniques like hot air reflow, infrared heating, and precision soldering tools are integral to achieving accurate and reliable rework outcomes.

Understanding PCB Repair: What It Involves

PCB repair involves diagnosing and fixing defective components or traces on a printed circuit board to restore its original functionality. Techniques commonly used include soldering, component replacement, and trace restoration, which require precision and expertise to avoid further damage. Understanding PCB repair helps you determine when careful correction is more cost-effective than complete board replacement.

Key Differences Between PCB Rework and PCB Repair

PCB rework involves modifying or correcting specific components on a printed circuit board to fix assembly errors or improve performance, typically done during the manufacturing process. PCB repair focuses on restoring damaged or faulty areas caused by wear, environmental factors, or electrical failures, ensuring the board's functionality is retained. Key differences lie in their application timing--rework occurs immediately after assembly while repair addresses operational failures--and the scope, with rework targeting component adjustments and repair dealing with damage remediation.

Common Scenarios for PCB Rework

PCB rework commonly occurs in electronics manufacturing when components are misaligned, solder joints are defective, or faulty chips need replacement to meet quality standards. Typical scenarios include correcting assembly errors, modifying circuit designs, and addressing issues from initial testing phases before final product deployment. Effective rework ensures functionality without the need for a complete PCB repair, saving time and reducing manufacturing costs.

Typical Cases Requiring PCB Repair

Typical cases requiring PCB repair include damaged traces, broken pads, or malfunctioning components due to physical impact or manufacturing defects. Repair processes often address issues such as short circuits, open circuits, and solder joint failures to restore functionality. You may need PCB repair when troubleshooting reveals defects that cannot be resolved through rework alone, emphasizing the importance of accurate diagnosis.

Tools and Techniques Used in PCB Rework

PCB rework involves precise tools such as hot air rework stations, soldering irons with adjustable temperature control, and microscopic inspection systems to remove and replace components without damaging the board. Techniques include controlled heating for desoldering, solder paste application, and reflow soldering to ensure reliable electrical connections and minimize thermal stress. Advanced methods like infrared rework and ultrasonic cleaning complement these tools, allowing technicians to restore complex multilayer PCBs effectively.

Essential Equipment for Effective PCB Repair

Effective PCB repair requires essential equipment such as a precise soldering station, hot air rework tool, multimeter, and magnification devices to ensure accuracy. High-quality flux and desoldering tools help remove damaged components without harming the board, while temperature-controlled workbench environments prevent further damage. By using the right tools, you can significantly improve the success and reliability of your PCB repair efforts.

Cost Implications: PCB Rework vs PCB Repair

PCB rework involves modifying or correcting specific sections of a printed circuit board, often resulting in lower immediate costs compared to full PCB repair, which may require extensive component replacement or board refurbishment. However, rework can increase long-term expenses if not properly executed, as it may lead to recurring faults or reduced board reliability. Your decision should weigh initial cost savings against potential future repairs and operational downtime.

Choosing the Right Approach: When to Rework and When to Repair

Determining whether to rework or repair a PCB depends on the scope of the defect and the impact on functionality. PCB rework involves targeted corrections like component replacement or soldering fixes for minor issues, ensuring minimal disruption and preserving board integrity. Your decision should prioritize cost-effectiveness and reliability, opting for repair only when extensive damage compromises the circuit's performance or when rework is impractical.

PCB rework vs PCB repair Infographic

solderic.com

solderic.com