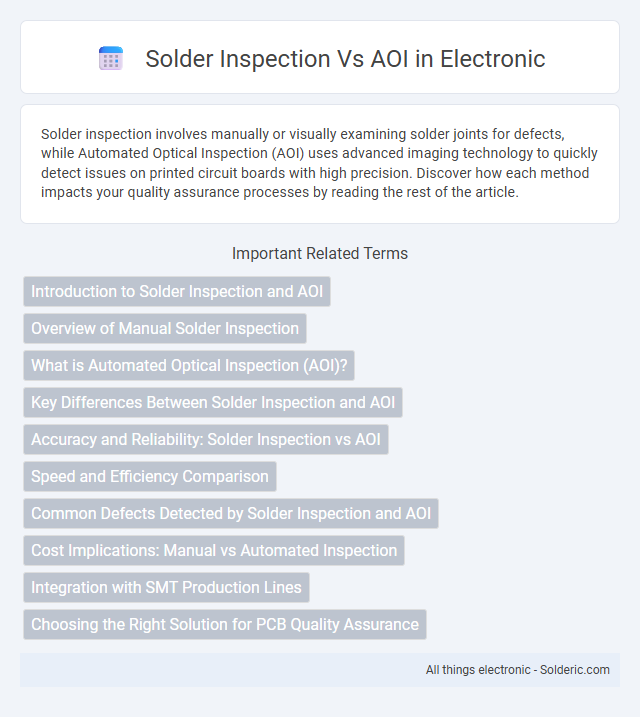

Solder inspection involves manually or visually examining solder joints for defects, while Automated Optical Inspection (AOI) uses advanced imaging technology to quickly detect issues on printed circuit boards with high precision. Discover how each method impacts your quality assurance processes by reading the rest of the article.

Comparison Table

| Aspect | Solder Inspection | Automated Optical Inspection (AOI) |

|---|---|---|

| Purpose | Detects solder joint quality and defects. | Identifies defects in assembled PCBs including solder, component placement, and assembly errors. |

| Inspection Type | Manual or automated visual/solder-specific inspection. | Automated imaging and algorithm-based inspection. |

| Speed | Slower, dependent on operator skill if manual. | High throughput, fast inspection cycle. |

| Defect Detection | Detects solder bridges, insufficient solder, voids, and fillet issues. | Detects solder defects plus missing components, misalignments, polarity errors. |

| Accuracy | High for solder-specific issues but subjective if manual. | Consistent and repeatable with advanced image processing. |

| Equipment Cost | Lower cost for manual inspection, moderate for automated solder inspectors. | Higher initial investment for AOI machines. |

| Use Case | Focused on solder joint quality verification. | Comprehensive PCB assembly quality control. |

Introduction to Solder Inspection and AOI

Solder inspection and Automated Optical Inspection (AOI) are essential processes in electronics manufacturing that ensure the quality and reliability of solder joints on printed circuit boards (PCBs). Solder inspection typically involves manual or automated methods to detect defects such as insufficient solder, bridging, or cold joints, while AOI uses high-resolution cameras and image processing algorithms to quickly identify surface defects and assembly errors. Your production line can benefit from integrating both techniques to achieve comprehensive quality control and reduce risks of functional failures.

Overview of Manual Solder Inspection

Manual solder inspection involves visually examining solder joints using magnification tools to identify defects such as insufficient solder, bridging, or cracks. This process relies heavily on the inspector's experience and keen eye to detect issues that automated optical inspection (AOI) systems might miss due to complex component layouts or varying solder joint appearances. Your quality control can benefit from integrating manual solder inspection to complement AOI, ensuring a thorough evaluation of solder connections.

What is Automated Optical Inspection (AOI)?

Automated Optical Inspection (AOI) is a high-precision imaging technology used to detect defects in solder joints and electronic assemblies by capturing detailed images and comparing them to predefined quality standards. This process enhances the accuracy and speed of identifying soldering issues such as insufficient solder, bridging, or misalignment, which are critical for maintaining product reliability. Your manufacturing quality control benefits from AOI's ability to provide consistent, objective inspection results without human error.

Key Differences Between Solder Inspection and AOI

Solder inspection specifically examines the quality and integrity of solder joints to ensure proper electrical connections and mechanical strength, while AOI (Automated Optical Inspection) uses advanced imaging technology to detect a broad range of defects on PCB assemblies, including solder joint issues. AOI is faster and more comprehensive for identifying surface-level defects and component placement errors, whereas solder inspection typically involves detailed, manual or semi-automated analysis focused solely on solder quality. Understanding these key differences helps you choose the right inspection method for optimizing your PCB manufacturing process and ensuring product reliability.

Accuracy and Reliability: Solder Inspection vs AOI

Solder inspection offers high accuracy by directly assessing solder joint quality through visual and x-ray analysis, detecting defects like voids and insufficient solder. Automated Optical Inspection (AOI) provides reliable, rapid evaluation using high-resolution imaging to identify surface defects and component misplacements but may miss hidden solder joint issues. Combining both methods enhances overall inspection reliability by leveraging solder inspection's depth with AOI's speed and surface-focused accuracy.

Speed and Efficiency Comparison

Solder inspection often relies on manual or semi-automated techniques that can be time-consuming and subject to human error, whereas Automated Optical Inspection (AOI) offers rapid, real-time analysis of solder joints with high precision. AOI systems accelerate production by quickly detecting defects such as solder bridges, insufficient solder, and misaligned components, significantly improving throughput and reducing downtime. Your manufacturing process benefits from AOI's consistent speed and efficiency, enabling faster quality control without compromising accuracy.

Common Defects Detected by Solder Inspection and AOI

Solder inspection primarily detects defects such as solder bridging, insufficient solder, solder balling, and tombstoning caused by poor solder paste application or reflow issues. Automated Optical Inspection (AOI) identifies surface defects including solder joint irregularities, component misalignment, missing components, and lifted leads by capturing high-resolution images and comparing them to a predefined template. Both methods are crucial in ensuring PCB assembly quality, with solder inspection focusing on solder-specific faults and AOI providing a broader defect detection scope.

Cost Implications: Manual vs Automated Inspection

Manual solder inspection incurs higher labor costs and increased inspection time, limiting throughput and scalability in production environments. Automated Optical Inspection (AOI) systems require significant upfront investment but reduce long-term operational expenses by accelerating inspection speed and minimizing human error. AOI offers a cost-effective solution for large-scale manufacturing with consistent quality assurance, while manual inspection remains viable for low-volume or prototype phases due to lower initial expenditure.

Integration with SMT Production Lines

Solder inspection systems and AOI (Automated Optical Inspection) play distinct yet complementary roles in SMT production lines, with solder inspection focusing specifically on the quality and integrity of solder joints, ensuring strong electrical connections and reducing the risk of defects. AOI systems are integrated to detect component placement errors, missing parts, and surface defects early in the process, enhancing overall production efficiency. Your SMT line benefits from combining both technologies to maximize defect detection and maintain high yields without sacrificing speed.

Choosing the Right Solution for PCB Quality Assurance

Solder inspection and Automated Optical Inspection (AOI) play crucial roles in PCB quality assurance, with solder inspection specifically targeting solder joint integrity while AOI provides comprehensive evaluation of component placement and solder defects. Choosing the right solution depends on your PCB complexity and production volume, as solder inspection excels in detecting solder-related issues, whereas AOI offers faster, automated defect detection across multiple layers. Integrating both technologies can optimize your quality assurance process by ensuring high reliability and reducing rework costs.

Solder inspection vs AOI Infographic

solderic.com

solderic.com