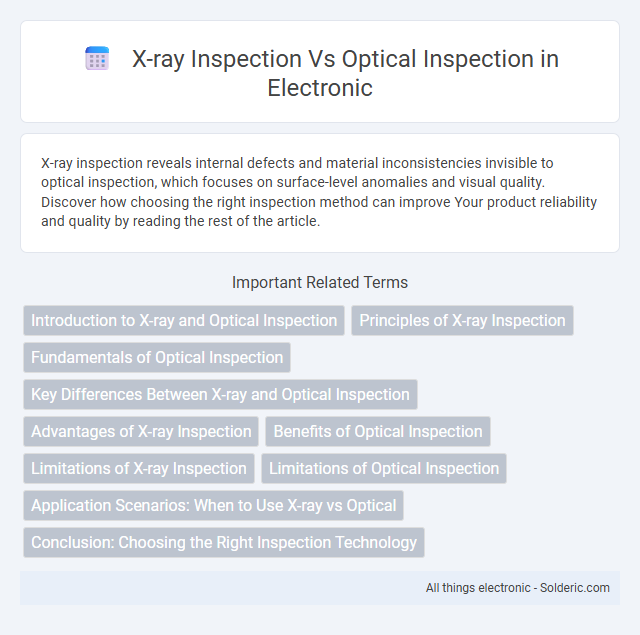

X-ray inspection reveals internal defects and material inconsistencies invisible to optical inspection, which focuses on surface-level anomalies and visual quality. Discover how choosing the right inspection method can improve Your product reliability and quality by reading the rest of the article.

Comparison Table

| Feature | X-ray Inspection | Optical Inspection |

|---|---|---|

| Technology | Uses X-ray radiation to see internal structures | Uses visible light to inspect surface features |

| Inspection Depth | Internal and hidden defects detection | Surface-level defect detection only |

| Common Applications | PCB inspection, weld quality, internal cracks | Surface defects, alignment, color, shape |

| Resolution | High for internal structures | High for surface details |

| Speed | Moderate to slow, depends on complexity | Fast, real-time inspection possible |

| Cost | Higher due to specialized equipment | Lower and more cost-effective |

| Safety | Requires radiation safety protocols | Safe, non-radiative |

| Limitations | Higher cost, radiation risk | Cannot detect internal defects |

Introduction to X-ray and Optical Inspection

X-ray inspection utilizes high-energy electromagnetic waves to penetrate materials, revealing internal defects and structural inconsistencies undetectable by surface-level analysis. Optical inspection relies on visible light and advanced imaging systems to evaluate surface features, dimensions, and color variations with high resolution. Both methods serve critical roles in quality control, with X-ray excelling in non-destructive internal examination and optical inspection specializing in surface defect identification.

Principles of X-ray Inspection

X-ray inspection uses high-energy electromagnetic waves to penetrate materials and reveal internal structures, detecting defects such as voids, cracks, or foreign objects that are invisible to optical inspection. Unlike optical inspection, which relies on surface visualization through cameras and lighting, X-ray inspection captures detailed cross-sectional images by measuring the differential absorption of X-rays within the object. Your quality control processes benefit from X-ray principles by enabling non-destructive evaluation of internal features, ensuring thorough and accurate inspection beyond surface-level analysis.

Fundamentals of Optical Inspection

Optical inspection relies on visible light and high-resolution cameras to detect surface defects, color variations, and dimensional discrepancies in products. This technique uses image processing algorithms to analyze visual features such as texture, shape, and contrast, enabling precise defect identification on external surfaces. Optical inspection is widely applied in industries like electronics, pharmaceuticals, and manufacturing for rapid, non-destructive quality control.

Key Differences Between X-ray and Optical Inspection

X-ray inspection uses high-energy waves to penetrate materials and reveal internal defects, while optical inspection relies on visible light to examine surface features. X-ray systems can detect hidden flaws such as voids, cracks, or misalignments inside components, unlike optical methods which are limited to surface-level analysis. Your choice between these inspection techniques depends on whether internal structure analysis or surface quality assessment is the primary requirement.

Advantages of X-ray Inspection

X-ray inspection offers superior capability to detect internal defects such as voids, cracks, and component misalignments that optical inspection cannot reveal. It provides non-destructive testing, allowing you to analyze the integrity of materials and assemblies beneath surfaces without disassembly. This advanced imaging technique enhances quality control by identifying hidden flaws in complex electronic components and industrial parts.

Benefits of Optical Inspection

Optical inspection provides high-resolution surface imaging, enabling precise detection of visible defects such as scratches, misalignments, and color variations that X-ray inspection might miss. This method is non-invasive and cost-effective, making it ideal for real-time quality control in manufacturing environments. Your production process benefits from faster inspection speeds and easier integration into automated systems, enhancing overall efficiency.

Limitations of X-ray Inspection

X-ray inspection faces limitations such as difficulty detecting surface-level defects and challenges with materials that have similar densities, which reduces contrast and defect visibility. It also involves higher operational costs and safety concerns due to radiation exposure compared to optical inspection. Furthermore, the resolution of X-ray imaging can be insufficient for identifying extremely fine surface details that optical inspection methods capture more effectively.

Limitations of Optical Inspection

Optical inspection is limited by its inability to detect subsurface defects or internal structural anomalies, as it relies solely on visible light reflection from surfaces. It struggles with inspecting complex assemblies where components are hidden beneath the surface or inside opaque materials. This technique also faces challenges in identifying minute internal voids, solder joint issues, or foreign objects within electronic components, making X-ray inspection essential for comprehensive quality control.

Application Scenarios: When to Use X-ray vs Optical

X-ray inspection excels in detecting internal defects, such as voids, cracks, or misalignments within components, making it ideal for industries like electronics manufacturing, aerospace, and automotive quality control. Optical inspection is best suited for surface-level analysis, identifying visible defects such as scratches, discoloration, or component misplacement on PCBs and assembly lines. Use X-ray inspection when internal integrity is critical for safety and performance, while optical inspection is more efficient and cost-effective for surface quality and visual alignment checks.

Conclusion: Choosing the Right Inspection Technology

X-ray inspection offers superior detection of internal defects, such as voids, cracks, and foreign materials, which optical inspection cannot reveal due to its surface-level analysis capabilities. Optical inspection excels in identifying surface anomalies like scratches, color variations, and misalignments with faster processing and lower operational costs. Your choice between X-ray and optical inspection should align with the specific quality standards and defect types relevant to your product to ensure optimal inspection accuracy and efficiency.

X-ray inspection vs optical inspection Infographic

solderic.com

solderic.com